ARBOR SP Series HMI Effectively Optimizes Factory Quality Control and Vehicle Management

At Vietnam’s feed production plant, it is crucial to ensure the quality and traceability of raw materials. To optimize this process, they integrated ARBOR's Panel PC SP-120R-1J64 into their vehicle management system, particularly in the sample collection area. This case study explores how the SP-120R-1J64, along with RFID technology, played a pivotal role in streamlining operations and maintaining high-quality standards.

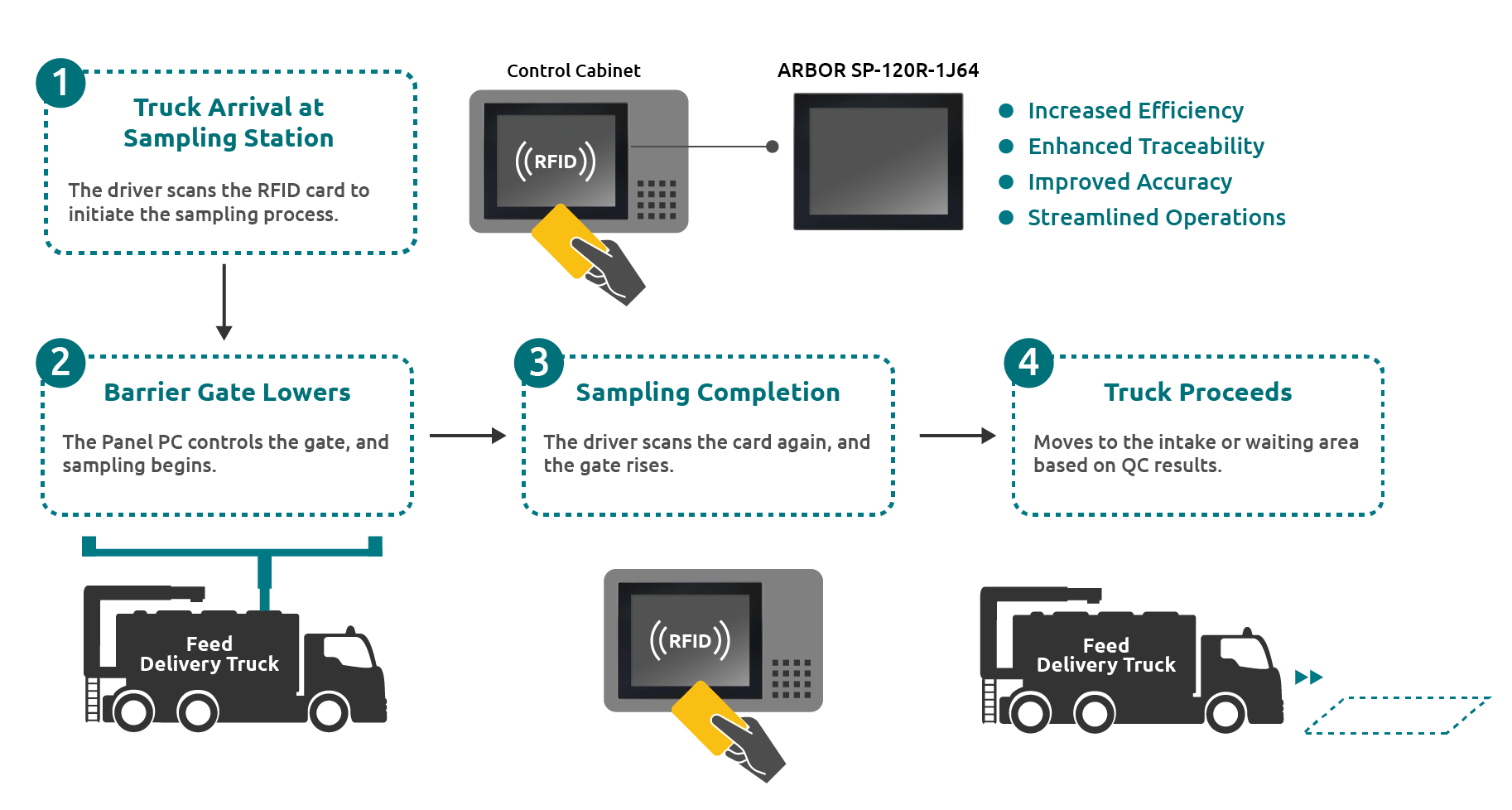

The ARBOR Panel PC SP-120R-1J64 is installed within a control cabinet that also includes an RFID reader, a notification speaker, and a barrier gate. This setup functions as a terminal in vehicle management system, primarily used in the raw material sampling area.

When a delivery truck arrives at the sampling station, the driver uses an RFID card to initiate the sampling process. Upon scanning the card at the Panel PC, the barrier gate automatically lowers, allowing the sampling procedure to begin. The Panel PC serves as the central control interface, ensuring that all actions are accurately logged and monitored. Once the sampling is complete, the driver scans the card again. This action triggers the barrier gate to rise, permitting the truck to proceed either to the intake area or to a designated waiting area until the quality control (QC) results are available.

Benefits and Outcomes

The integration of the ARBOR Panel PC SP-120R-1J64 into C.P.’s vehicle management system has brought several key benefits:

1. Increased Efficiency: The automated system reduces the time needed for sample collection, minimizing delays and improving overall plant throughput.

2. Enhanced Traceability: Each truck's movement and the corresponding sampling data are logged and can be easily accessed for quality control and auditing purposes, ensuring transparency and traceability in the production process.

3. Improved Accuracy: By automating the sampling initiation and barrier control, the likelihood of human error is significantly reduced, ensuring that only materials meeting stringent quality standards enter the production process.

4. Streamlined Operations: The integration of RFID technology with the Panel PC ensures that the process is smooth, with clear instructions and feedback provided to the driver via the notification speaker.

The ARBOR Panel PC SP-120R-1J64 has proven to be a valuable asset in C.P. Vietnam’s feed production plant, particularly in enhancing the efficiency and reliability of their raw material sampling process. By integrating this technology into their vehicle management system, C.P. has successfully maintained high standards of quality control while optimizing operational efficiency. This case study highlights the importance of leveraging advanced technology to meet industry demands and uphold rigorous quality standards in feed production.